April 25, 2023

Kyel Godfrey-Ryan

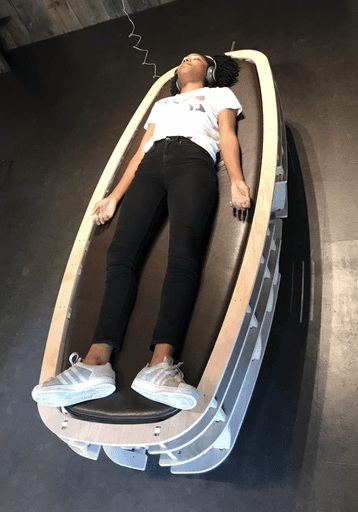

All of our data was coming back clean and the next step was building our own instrument. We sourced industrial engineers who worked in partnership with the family owned woodworking facility to create our first prototype. The goal was to build an instrument that tuned the human body. We wanted to build an acoustical device that carried our frequencies with precision. We needed a modern, yet timeless appearance that could visually adapt into both public locations and offices. It also had to be sustainable, durable and beautiful. We were inspired by the design of wooden instruments and modeled the TUNE after the inside of a violin, as to create the resonance needed for an instrument designed for the body. Though it took several iterations and close to a year of refinements, nothing compares to seeing the first model released. Below is an image of Jas Neal, the head of operations at that time laying on the first prototype. We are currently in production of the sixth model of the TUNE.

Jasmine Neal, 2018, Connecticut, laying on our first prototype.

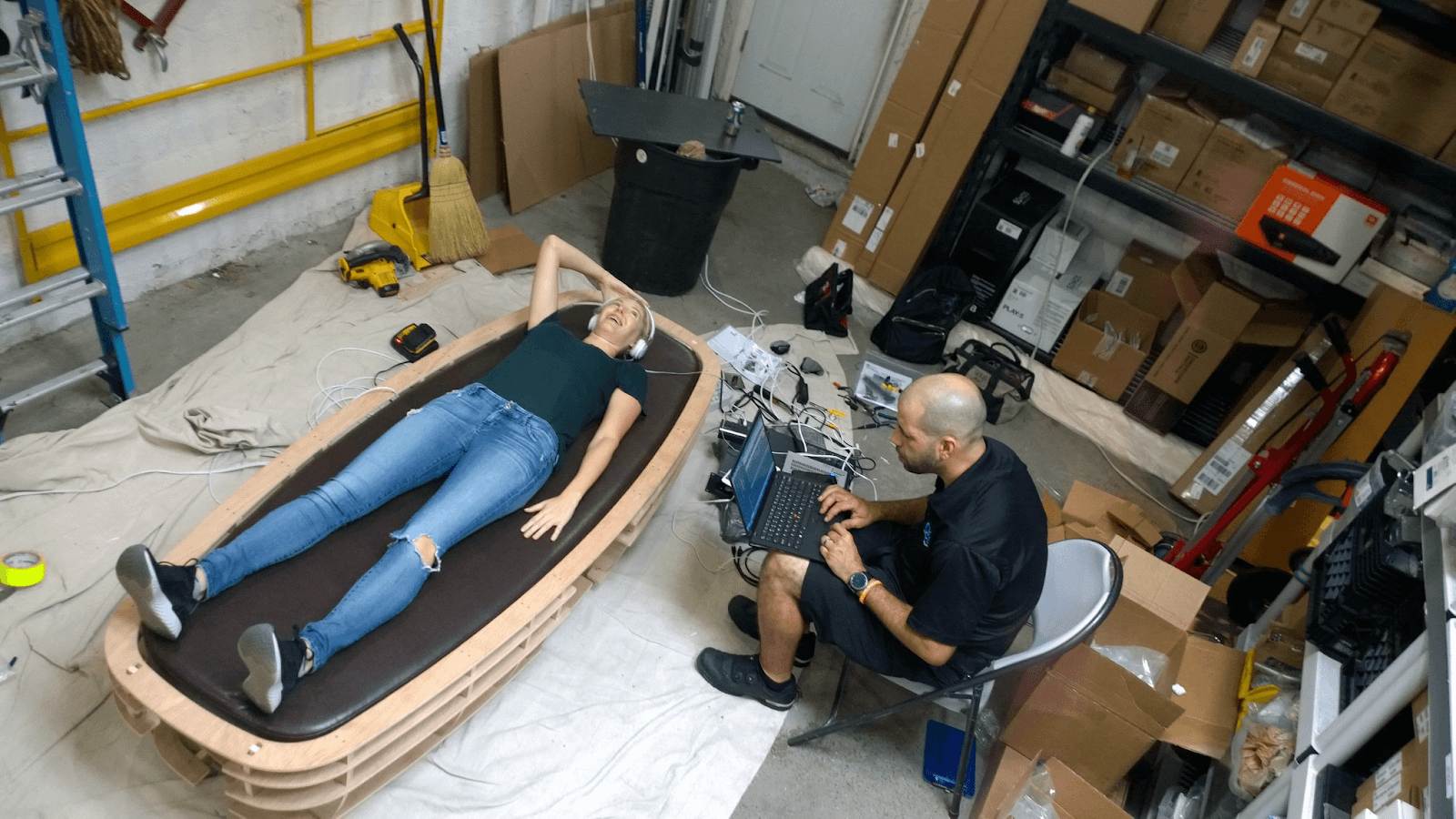

We worked out of a garage space in Greenpoint with acoustical engineers on our hardware to create the most powerful and precise vibrations. I was building something that hadn’t been done before, so there wasn’t a roadmap to follow. Trial and error, testing frequency ranges, playing with crossfading, altering the design of the frame in several ways through this time was equally fun and frustrating at times. During the winter months, we had to bring in heaters to warm up the wires to get them to function properly. We were a true start up in every way.

Below is the image of the first session that tested with the target range we wanted for the frequencies and the neural music balance.

August 2018, Greenpoint Brooklyn with Cole AV and our industrial designer who snapped the photo.

My goal for TUNE was to operate as a B2B company and a publicly accessible offering at the same time. I wanted to partner with large, credible companies who also would test our technology before implementing it into their ecosystem. At the time, we were the only company in our lane and though our testing and experiences demonstrated the power and potential of our technology. We had the science to prove this worked and over 5,000 sessions tested with audiences all over the country, but I preferred for Fortune 100 companies to be the ones who publicly championed our technology.

Statham Woodworking, Connecticut, 2018 testing out new materials for the TUNE